Patented Technology The STECTURE® INTEGRATED PROCESS

Why do we build? We build because our dreams for the future see us in a home unlike any on the market. We build because the sunset view we have in mind has yet to be framed. We build because the perfect home has yet to be designed: a home custom built for you.

Stecture is here to help you achieve that dream. Using a step-by-step approach, we make the homebuilding experience uniquely enjoyable. Our seamless, integrated services streamline the process of building a home into a predictable, thoroughly planned and executed project.

Let’s Talk

Our Sales Team will answer any questions you may have about the STATURE building system and process. We would also love to learn more about you: your ideal home, your interests and more.

Your Lot

Our integrated combination of rigid and foam insulation reduces energy loads, and provides superior comfort and energy savings of up to 90% compared to traditional construction.

A Perfect Match

Stecture recommended high performance doors and windows complete the thermal envelope and provide breathtaking views without sacrificing performance..

1

PLANNING

While building a home may appear to be a daunting endeavor, in reality it consists of a number of predictable steps. During the Planning Stage, BONE Structure’s Project Managers will guide you through the planning phase and go over the next steps of the BONE Structure process in detail. By the end of this stage, your requirements, your preferred timeline and your target budget will be explored further, and your homebuilding project will begin to take shape.

2

CONCEPTUAL DESIGN

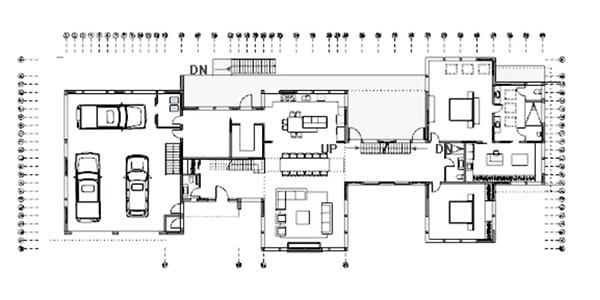

Feel inspired! You have a blank canvas, it’s time to daydream. Whether you start from one of our inspirational models or we design a full custom home, the BONE Structure architectural and structural engineering services are here to bring your vision to reality. At the end of this stage, the main elements of your home will have been decided using a 3D Conceptual Model: site plans, space programming, building orientation, building massing, and preliminary finishes..

Anticipating the permitting stage, and to ensure the design of your home progresses smoothly, BONE Structure researches on your behalf: site analysis, local building codes, by-laws and even preliminary structural and technical studies are completed at this stage.

Concept Presentation

A final conceptual design presentation ensures all major design decisions have been covered and finalized. With these design choices made, a preliminary costing of the project is performed before moving on to the next stage.

Read more

Project Timeline

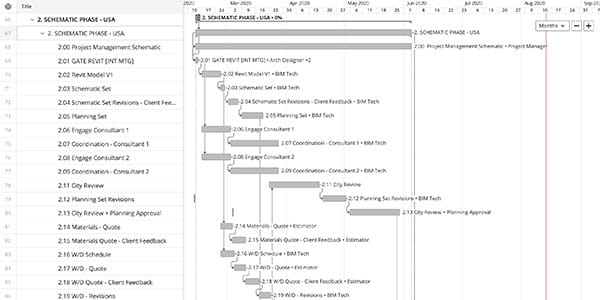

With the conceptual design complete, your Project Manager can now establish a project timeline and begin coordinating with any required third parties to prepare the next steps.

Read more

Project Management

Each step of the Stecture process follows a predetermined set of tasks and milestones. Specific project parameters are added to this timeline to establish the overall duration of each phase.

Read more

3

SCHEMATIC DESIGN & PERMITTING

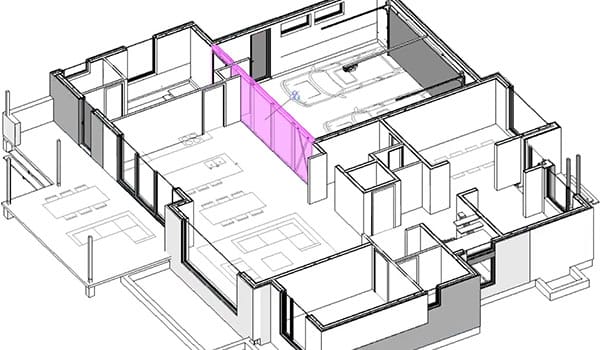

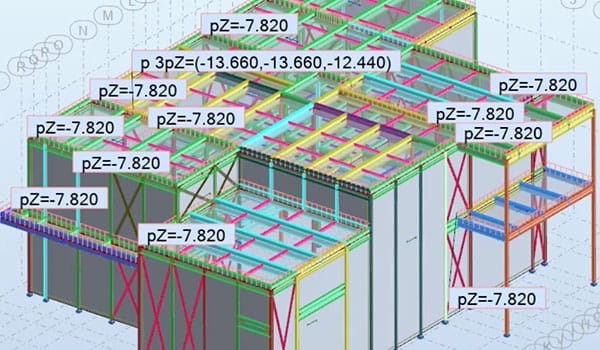

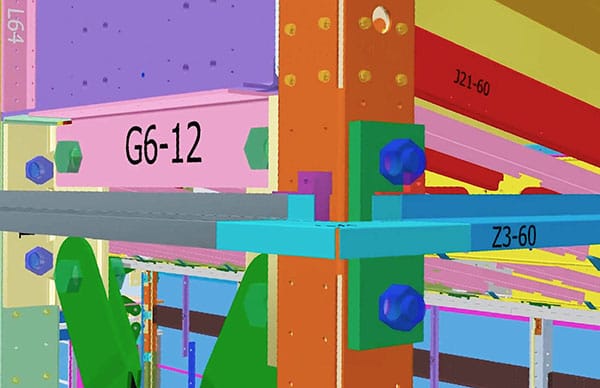

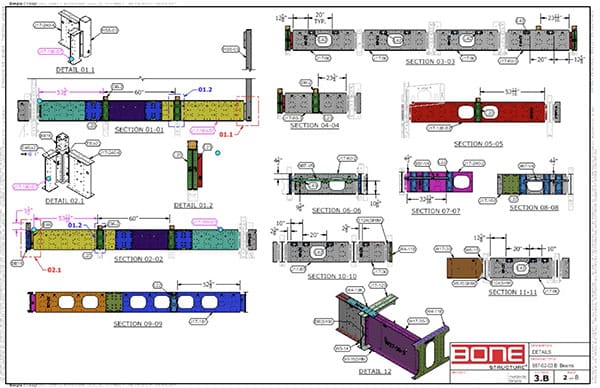

Intelligent design, down to the last detail: STECTURE uses Building Information Modeling (BIM) for every single home designed. During the Schematic Design stage, the Conceptual Model of your home is developed into a detailed 3D Coordination Model. This model allows for full integration and coordination across our teams and external collaborators. All assumptions from the Conceptual Model are validated at this stage, and potential concerns are identified and solved in the software. This eliminates unforeseen situations on the work site.

STECTURE can also identify and introduce you to a builder best suited for your project, should you require one. A detailed project budget is prepared and presented at this stage, in coordination with all key players involved.

4

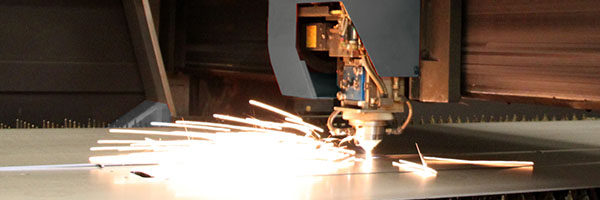

PRODUCTION & SITE PREPARATION

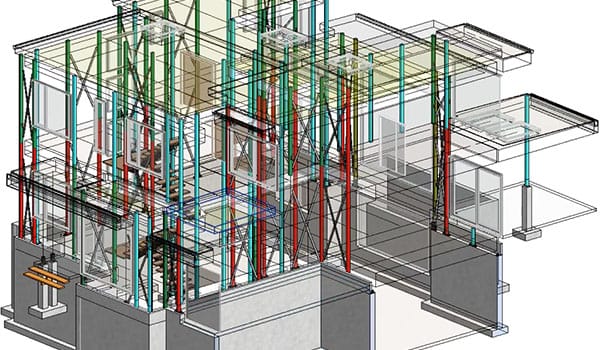

The steel structure of every STECTURE home built is assembled virtually before being sent to production: every steel component, every insulation panel, every door and window. The average structure of a STECTURE home contains over 12,000 components in the Structural Model.

5

STECTUREASSEMBLY

Insulation

Doors & Windows

Finishes

6

MECHANICAL SYSTEMS & FINISHES

Once the STECTURE thermal envelope has been wrapped up, plumbing, electrical and mechanical systems can be completed, as well as interior and exterior finishes. This final step is typically executed by the Building Partner, with BONE Structure offering turnkey services in certain markets.

STECTURE beams and wall compositions are designed with MEP (Mechanical, Electrical and Plumbing) in mind, which can be easily installed with no cutting or piercing required. Various mechanical systems (or combinations) can be used with STECTURE, and they are often downsized thanks to the efficiency of our thermal envelope.